Do You Really Need a Prototype?

Jan 03, 2022

Early stage medical device innovators and entrepreneurs often feel that the first critical step in their new venture is to build a prototype. Without a prototype, these visionaries rely on verbal descriptions and rough diagrams to help articulate both the medical problem and their proposed solutions. A functional prototype advances the conversation with key stakeholders and builds the value of the medical device concept and business opportunity.

The challenging part is that prototypes cost money, and designers at the idea stage usually are in short supply of financial resources. While widespread availability of 3D printing and other rapid fabrication methods has reduced the costs of fabrication, rarely is prototyping a matter of simply fabricating parts. Prototyping is an output of a product development process, which most often involves detailed design and engineering efforts. Trying to build a prototype without investing in competent engineering and design is like trying to build a house without skilled carpenters, plumbers, and electricians. Typically, investing in a development process that would result in a functional and reliable prototype is much more costly than bootstrapping entrepreneurs are able to endure.

Eventually, to advance a medical device business, there certainly needs to be a prototype to demonstrate functionality and to serve as a testing platform. However, there may be more cost-efficient and less time-consuming methods that can be deployed, at an early stage, to generate the critical information needed to move the business forward.

So, what then is this critical information that needs to be addressed at the idea stage? Most often, the focus is, “will it work?” While this is a critical question, it often is only a small part of the challenges facing early stage medical devices, and should be expanded to include:

- Will it work within the clinical workflow?

- Will it work within the economic constraints of customers and payors?

- Will it work without infringing on existing intellectual property?

- Will it work within a development timeline and budget that is acceptable by investors?

- Will it work while meeting regulatory requirements for safety and efficacy?

Often, these other business risk factors (workflow, healthcare economics, intellectual property, regulatory affairs, etc.) are just as important — if not more so — than the product risk factor of functionality. Furthermore, addressing these business risk factors does not require designing, engineering, and prototyping. These factors can be addressed through secondary research and brief reviews with industry experts.

Before undertaking on any type of product development effort (including prototyping), these key risk factors should be thoroughly evaluated and documented. Even if these factors have been sufficiently addressed, and a prototype is the next logical step, it still is best to isolate the most critical product risks and target prototyping efforts on reducing them:

- Technology risk — Are there critical operating parameters that enable the device to meet performance expectations?

- User and customer risk — Will customers be inclined to adopt this new product and to incur the behavior changes that may be required for its use?

- Manufacturing risk — Are there existing, available manufacturing processes and materials that enable this product to be produced with reliability and scale potential?

It is tempting for designers to attempt tackling all of these product risk factors (and more) in a single prototype build. But, the reality is that prototyping is a process of experimentation. Very rarely does any experienced product development team get it right the first time. For novel medical devices, the ideal product development process anticipates change and builds in methods for adapting to unforeseen circumstances. It is a process that generates rapid prototypes focused on specific questions, and then uses an iterative approach to identify the optimal solutions.

Below are some methods that can be used to target these individual risk factors:

Prototyping To Address Technology Risk:

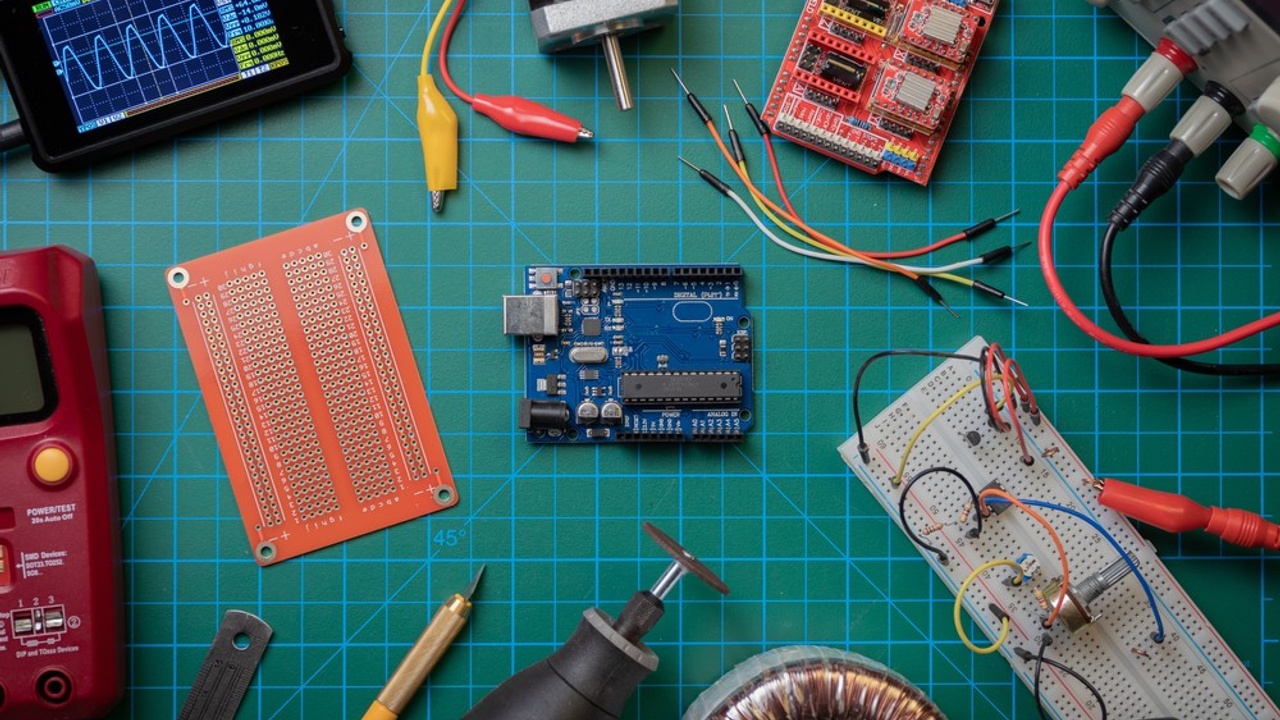

When new functionality needs to be developed and evaluated, it often is better to build a focused subsystem breadboard or a testing fixture. This approach focuses exclusively on the technical area of concern and provides means for swapping critical components — such as motors, springs, and sensors — in and out. It enables rapid experimentation to take place in arriving at the conditions that will result in ideal performance.

However, a breadboard developed with the intent of swapping components and optimizing parameters may be far from the ideal product form factor. Breadboards often are large and lacking aesthetic appeal, since they need to account for an array of interchangeable components. Still, prototyping through a breadboarding approach can be an effective and efficient means of reducing technology risk.

Prototyping To Address User And Customer Risk:

When developing a product that may not currently exist in the marketplace, gaining user feedback early in the development process is a crucial step. Too often, product developers assume that customers and users will adopt the novel product based on its merits — a gamble that often results in costly redesigns late in the design and manufacturing process.

But, addressing customer and user perspective rarely requires the new product’s full functionality. Often, sharing with target users an array of non-functional use-case mockups can yield greater feedback than sharing a single functional prototype. Customers care about the product’s end benefits, not the technology that enables those benefits. Attempts to quickly develop a functional prototype for user evaluation typically create an unrefined (i.e., bulky, non-ergonomic) contraption that tells you things you already know. Evaluating customer perceptions and concerns can be much more effectively accomplished through use-case mockups that focus on the end benefits to users, as well as the varying trade-offs that may need to be considered.

Investor Demonstration

When functionality is needed purely for demonstration purposes, often the fastest route for achieving this demonstration is cannibalization and repurposing of an existing product that has similar functionality. For example, one might take the electronics (e.g., wireless chip, sensors, power source) from a commercially-available consumer product and package them within a custom enclosure that has mechanical elements sufficient to perform a basic demonstration of the product and the value proposition.

Often, animations and renderings can supplement these demonstration prototypes to provide the visuals necessary to more clearly articulate the longer-term product vision. Rarely does a prototype need to be fully customized and executed perfectly for an investor to understand the value proposition. While a prototype may be one of the key preparations required for an investor pitch, most savvy investors will be more concerned with the business risk factors (regulatory pathway, intellectual property, etc.).

Which brings us full-circle to the question, “Do you really need a prototype?” Stated simply, a better approach is to list the numerous risks facing your new venture, and then deploy a product development strategy that reduces those risks through the most efficient means possible. Prototyping certainly will be a part of this risk-reduction strategy, but prototyping should not be considered the strategy itself.

Join the conversation

Drop your email below to receive these articles delivered to your Inbox as soon as they're published.